|

|

| Skanska UK Tunnelling Division (formerly known

as Cementation) is an important part of the Civil Engineering & Specialists

business stream of Skanska UK plc. Parent company Skanska AB is one of the

world's leading companies in construction and project management.

Skanska's underground construction, refurbishment and geotechnical projects include the largest, most complex and prestigious schemes in the United Kingdom, whether it be for rail, road or utilities. In keeping with its leading position Skanska UK holds safety, quality control and environmental considerations as top priorities. The Company is accredited under OHSAS 18001 for its safety management system, accredited to ISO 9001 for its quality management systems, and has ISO 14001 accreditation as part of its drive for consistently high environmental performance. |

|

Handling complexity Successful major tunnelling projects include the

Channel Tunnel Rail Link (CTRL), now under construction, in which Skanska

is a leading participant in four major contracts totalling over £500

million in value. All involved innovative solutions and true teamwork

in integration with the Client and consulting engineers as well as other

joint-venture contracting partners. Major features of the project included:

The project won the British Construction Industry Award (BCIA) Major Project Award. Earlier Skanska was also part of the joint venture redeveloping the original Stratford Station for London Underground. The underground works here consisted of jacking a 7.7m x 4.35m section concrete box structure over 54m under three sets of live railway routes during track possession periods. |

|

| Tunnel construction The tunnelling division was formerly the Cementation Mining & Construction businesses and undertook a wide range of UK-based and overseas projects, including the £46-million Contract 18 of the Hong Kong Strategic Sewage Disposal Scheme, tunnelling from Kwun Tong to Stonecutters Island through faulted hard rock with two tunnel boring machines, in joint venture with Gammon, and the £44-million Central, Western and Wan Chai sewer under the dense urban area of Hong Kong. Since 1985 Skanska has been part of the consortium that completed over 35 km of tunnels for the Greater Cairo Wastewater Project, Egypt, in a contract valued at £394 million. Tunnels in diameters from 1.20m to 5.00m, and 132 shafts of 4.85-5.00m i.d. and depths to 30m were constructed using earth-pressure-balance, mixed and slurry-shield tbms, compressed air working, and specialist sewer lining, all integrated with the local workforce. Back in London, work has been progressing in preparation for the planned cross-city Crossrail project. Skanska was responsible for constructing an 8.2-m diameter, 40m-deep draught-relief shaft below the 10m-deep basement of the Moorhouse development in the City. Work included dewatering the basal Thanet Sands with 17 wells, constructing the shaft with concrete segment lining, and monitoring for associated ground movements. The Moorhouse structure is designed to accommodate the shaft, future tunnels and associated railway structures. |

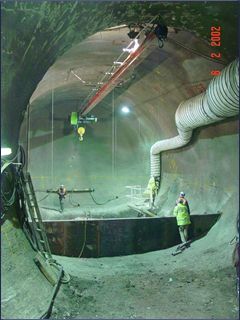

Sprayed Concrete Lining technique used for large underground excavations on the Channel Tunnel Rail Link |

| Refurbishment Recent activities have focused on specialist tunnel refurbishment and upgrade projects, including National Grid & Network Rail tunnels. The refurbishment and maintenance of the UK's underground assets are an increasingly important part of Skanska's business, which is also based on a wealth of experience with recent and earlier projects. Tunnels at various depths under Wimbledon, in south-west London, which carry high-tension electrical power cables for National Grid, were recently refurbished over a total length of 3.2 km. Typical work includes the installation of cable-cooling and fire-suppression systems. |

Refurbishment of 3.2 km of cable tunnels under Wimbledon, south-west London |

|

Reconstruction of the Horsfall Tunnel, on the Manchester to Normanton rail route was carried out in a £1.4 million contract for Railtrack. This required the complete rebuilding of a 30-m portal section, plus the renovation of the rest of the 250-m long tunnel lining within a 4-week rail-line possession. The work included retaining the hillside behind a 14m-high reticulated minipile wall (300 No. x 220mm-diameter to 16m depth), reinforced concrete construction, and trackwork. The project won the Yorkshire ICE Merit Award. In the water sector Skanska recently conducted repairs to the Ffestiniog hydropower station shaft in north Wales, and upgraded a fish-pass tunnel through hard rock at Conwy Falls, also in north Wales. For the Dartford Crossing road tunnels, to the east of London, which are a vital link in London's M25 orbital motorway route, Skanska was responsible for the replacement of deteriorated highway decking and tunnel lining cladding panels in the two bores in turn. |

|

Multi-disciplined

|

The new precast segment-lined service tunnel for the extended Harrods store awaits fitting out |

|

For more information on these and many other Skanska

tunnelling projects, or our vast range of tunnelling and underground refurbishment

and ground engineering techniques, contact: © tunnelbuilder ltd |